A Labour of Love

People are at the heart of everything we do. As such, you will not find any form of automation within the walls of our factory. Building a Bufori is a mammoth task that would be impossible to achieve without the passion that drives every single member of the Bufori team. Allow us to introduce the various departments involved in the creation of our masterpieces.

INTERIOR TRIM

A team of experienced Master trimmers is responsible for the creation of the stunning Bufori interiors. Beautiful full grain leather hides are carefully selected and cut into shape to fully cover the Geneva cabin. A well-trained eye and patience are paramount to achieve an immaculate interior finish.

COMPOSITE

Bufori has been using advanced composite materials since the inception of the company in 1986. As such, we have gained vast knowledge in the fast moving field of composites. Always eager to use the latest technologies and apply state-of-the-art techniques, our composite laminators work with utmost precision.

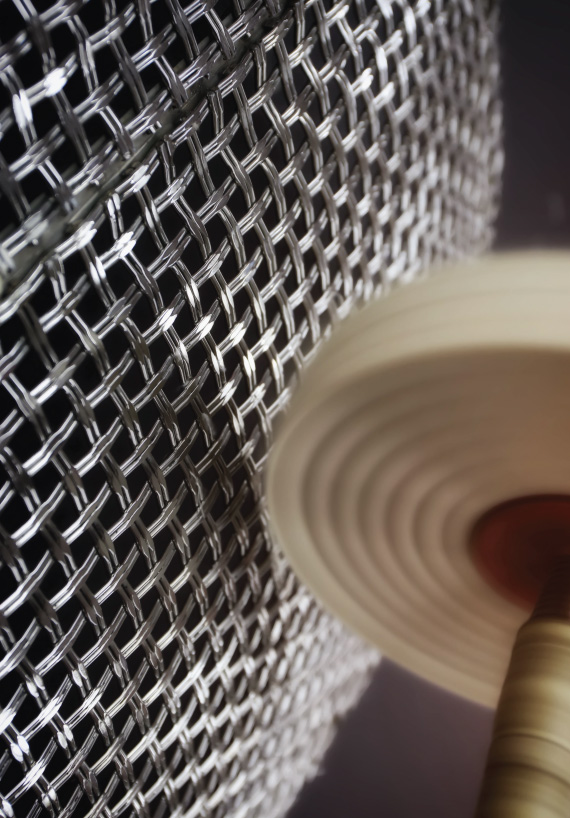

METAL WORKS

Metal forms a fundamental part of every Bufori, whether as an ornamental piece of brightwork or a structural component such as the chassis of the vehicle. We pride ourselves in the machine-like accuracy of our Tungsten-Carbide (TIG) welding, which we have elevated to a form of Art. The hand-polishing process of the iconic Bufori mesh grille is a demanding task that requires skill and patience.

ELECTRICAL & MECHANICAL

Running the wire harness and installing the engine is synonymous to creating the nervous system and heart of the automobile. Our talented Master Mechanics and wiremen work hand-in-hand to give life to each and every Bufori they build. Abiding to extremely strict standards, every step of the process is double and triple checked before a comprehensive PDI is conducted.

PRE & FINAL FITTING

The fitting of the Bufori interior is more than just joining the pieces of the puzzle. The individual trim panels are pre-fitted into the “naked” body to ensure consistent tolerances. Once the vehicle is painted and mechanically ready, the final fitters carefully assemble the trim parts under the watchful eye of the Master. Due to the many custom features in every Bufori, this tasks never becomes a routine.

PAINTING

One of the longest production steps is the painting stage, which also consists of tedious body preparation. Our talented painters then apply as many coats as necessary to achieve a rich, deep colour worthy of a Bufori, followed by a thorough polish that brings out a mirror-like shine.

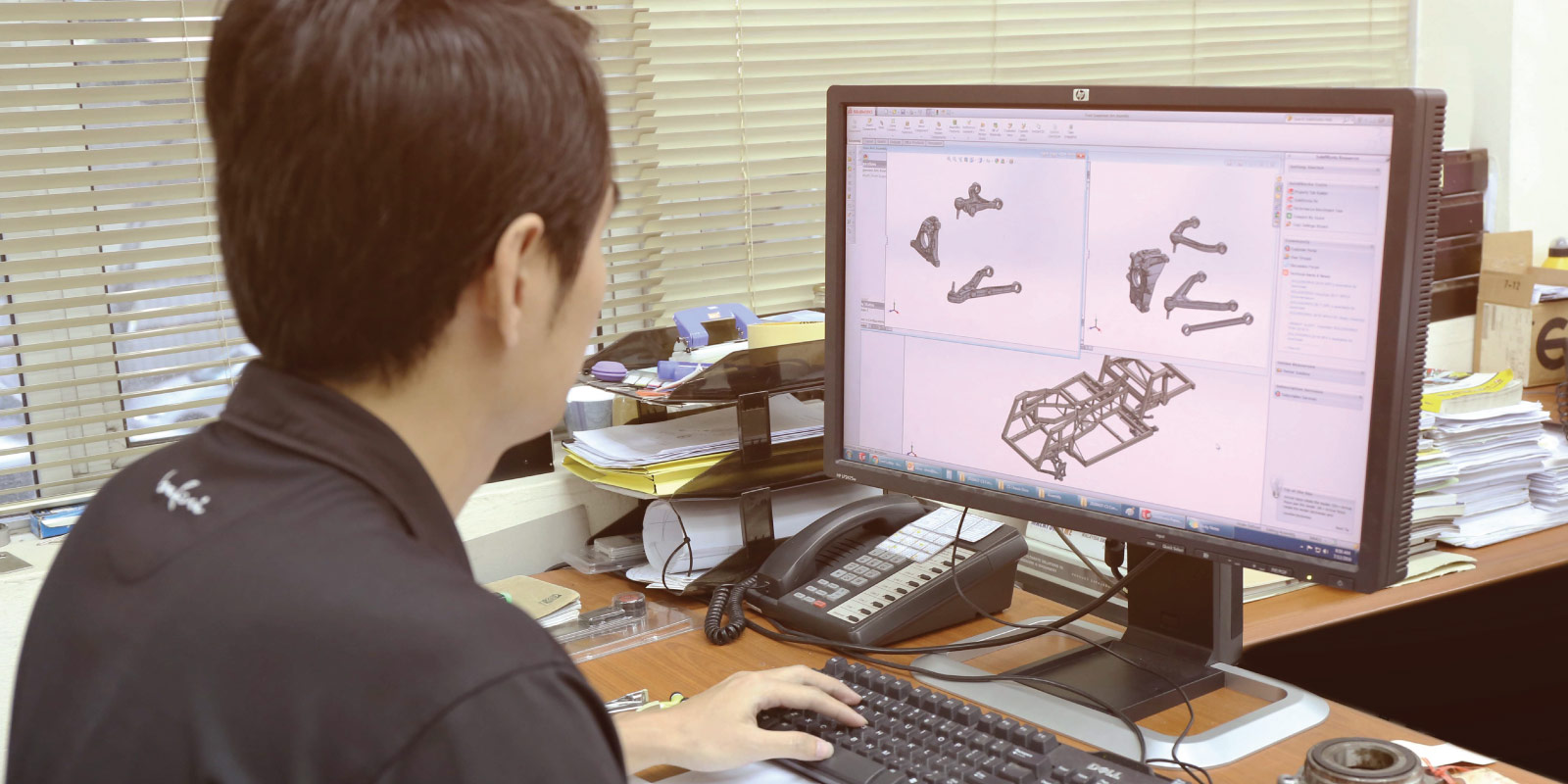

ENGINEERING

This is where it all begins. Using Computer Aided Design softwares, our engineers are instrumental in the development of new Bufori models. They are also in charge of setting up and overlooking the production processes. Furthermore, Bufori also offers automotive engineering services to third parties.

PRIDE OF MANUFACTURING

Bufori’s driving force is the sheer passion of every single team member. We see ourselves as the caretaker of the brand and take pride in even the smallest tasks that contribute to building your dream car. Eventually, our biggest reward is the smile on our customer’s face.